Research Group at KIT

Particles shape our world and everyday life: Macroscopic material and product properties are determined by interactions and processes at the microscopic level.

Our goal is to answer pressing questions about such agglomeration and breakage phenomena, especially when multiple materials come together. Understanding the dynamics of these heterogeneous interfaces is essential for optimizing manufacturing processes, improving material properties, and driving innovation in areas such as energy storage.

To achieve this, we emphasize the synergy between theoretical modeling and hands-on experimentation.

Group Leader

Experimental and theoretical work on selective hetero-agglomeration. Separation of microplastics via magnetic seeded filtration. PBE modeling and data integration via machine learning.

PhD Student

Experimental work on hetero-aggregation in flames. Multi-scale characterization with SAXS, TEM and AUC.

PhD Student

Multi-scale modeling with PBE and CFD-DEM for selective hetero-agglomeration. Parameter optimization and integration via machine learning.

PhD Student

Experimental and theoretical work on continuous battery slurry production with twin screw extruders. Focus on carbon black dispersion and slurry quality. Process simulation with SPH.

PhD Student

Investigation of the process-property relationships in the dry mixing of battery electrode materials using experimental and simulative methods. Determination of optimal conditions to achieve a homogeneous, free-flowing mixture for effective calendering.

PhD Student

Experimental work on continuous battery slurry production with twin screw extruders. Focus on the development of an automated process control strategy and a cleaning concept.

PhD Student

Theoretical work on model predictive control applied to redox flow batteries (RFBs). Part of the PREDICTOR research network, for development of RFB materials and technology.

Funding: DFG

Population balance models (PBMs) enable the simulation of agglomeration and breakage processes. However, the complexity

increases in multi-material systems due to heterogeneous surface properties and the need to consider all pairwise

interactions.

In this project, a multi-scale approach is used to determine the required kinetic rates (kernels): CFD-DEM simulations

at both macro- and micro-scale are integrated with experimental data. Machine learning models are then used to translate

these rates for use in both discrete and Monte Carlo PBMs. The overall goal is to establish a systematic methodology for

the calculation of hetero-agglomeration processes in arbitrary multi-material systems. This enhances process

transparency and control for a variety of applications.

Funding: DFG, SPP 2289

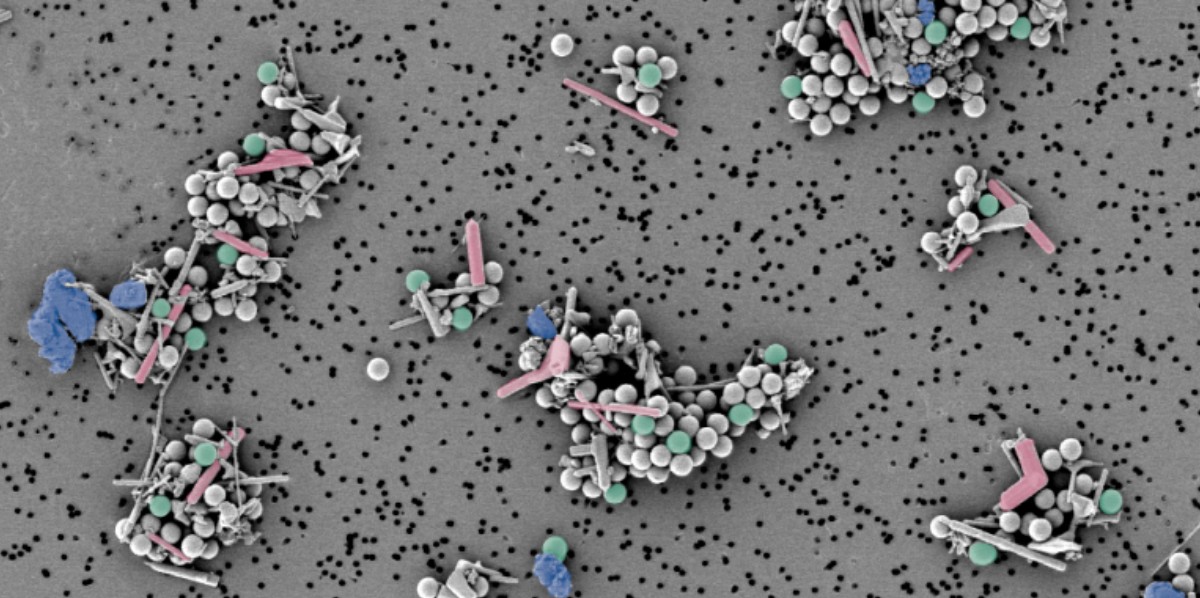

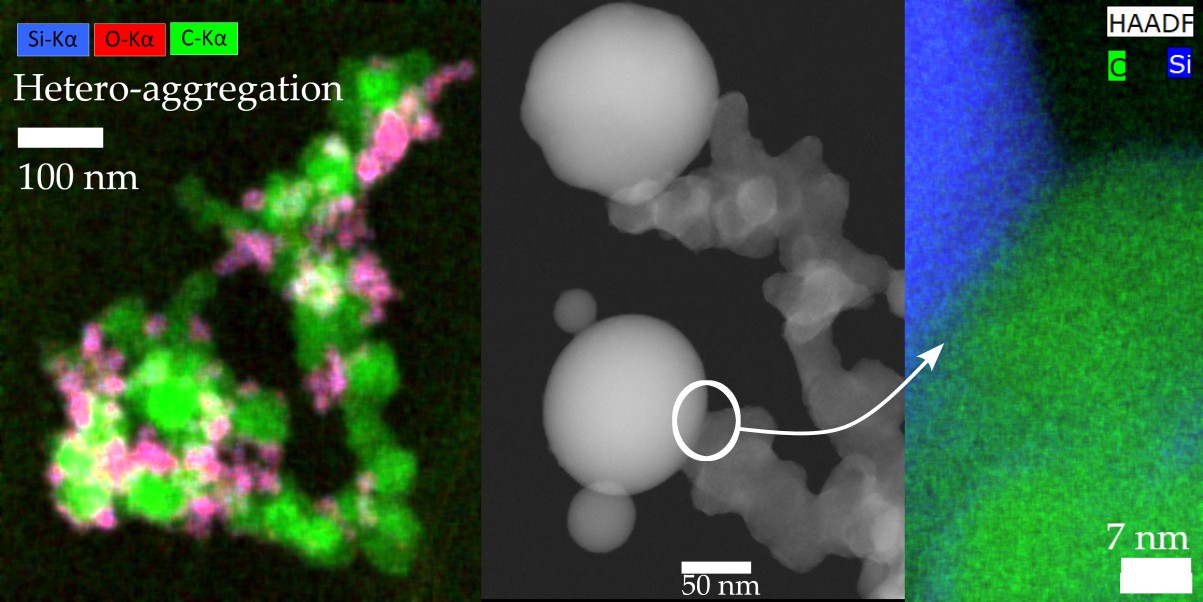

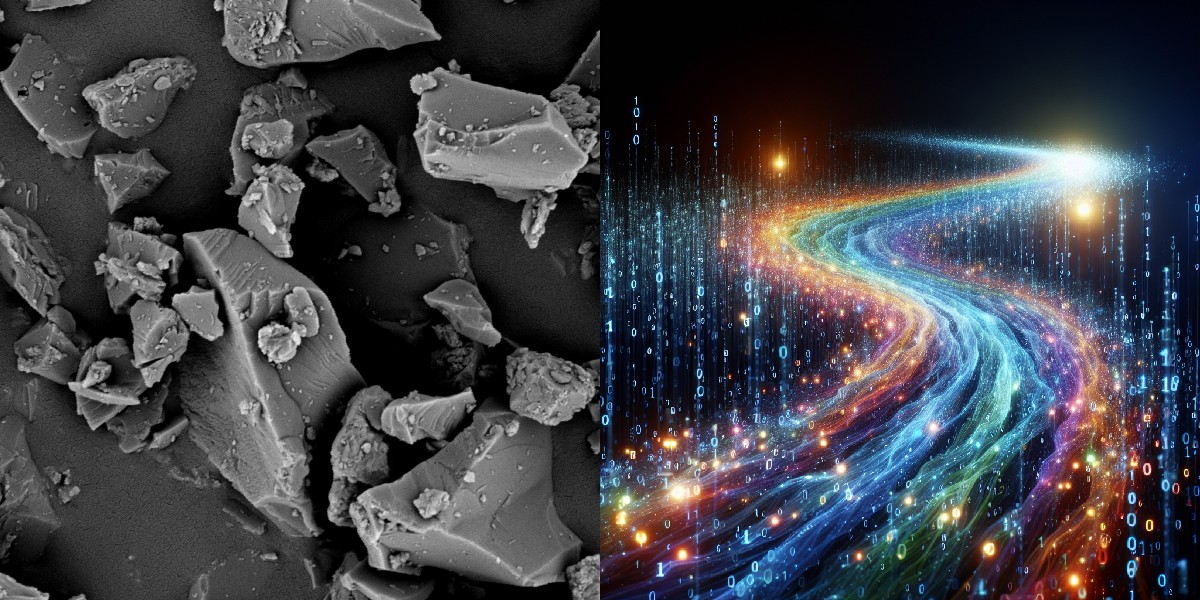

Nanoparticles are widely used in industrial products because they combine material inherent physio-chemical properties

with high surface to volume ratios. These properties are multiplied and complemented by the functional mixing with

other nanoparticle species. Subsequently, hetero-contacts are formed at the distinct interface of the two materials,

which are of fundamental importance for the desired functional properties of the mixture.

This project focuses on the improvement of carbon black properties for battery applications by hetero-aggregation with silica.

The characterization of the hetero-contact and the resulting mixing quality of the hetero-aggregates is still a major

challenge. Hence, the development of an extensive image analysis of the mixing quality with TEM in combination with

multi-scale particle analysis by SAXS and ADC is pursued. The combination of both methods provides holistic

information on all relevant length scales, leading to an understanding of the interaction between mixing quality and

aggregate properties. This comprehensive insight into the quantity and quality of the hetero-contacts is pivotal to

bridge the gap from aggregate properties to functional properties and the resulting material functions. Ultimately, it

is envisioned to determine which nanoscale structure is most beneficial for the application in batteries in order to

improve the manufacturing process of batteries as well as the electro-chemical performance.

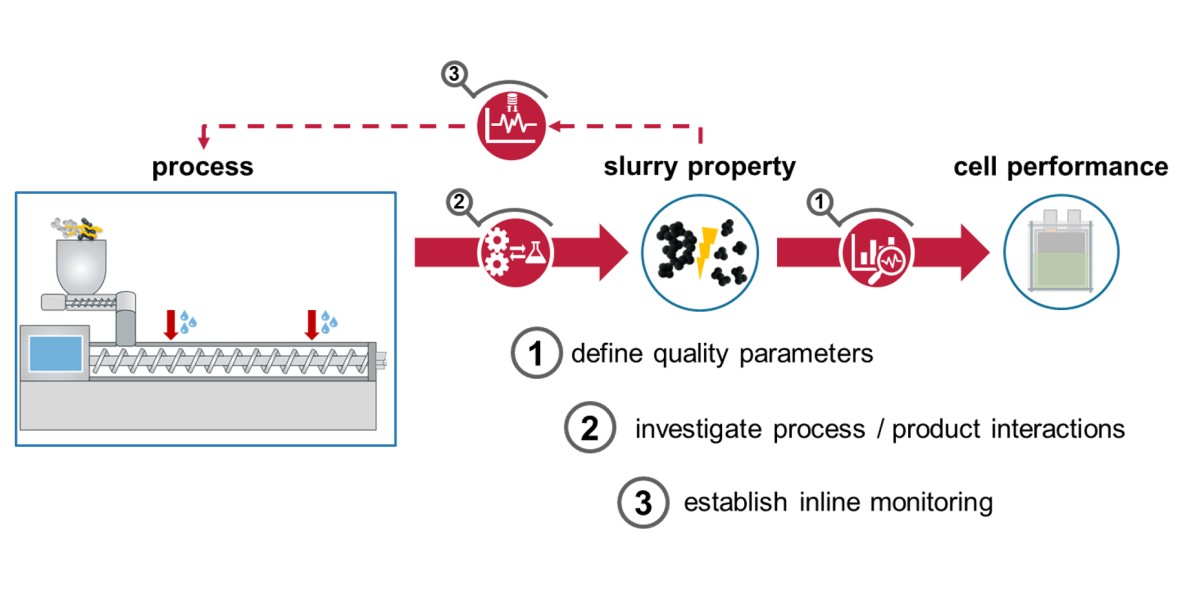

Funding: BMBF

This research project aims to reduce production costs and increase the product quality of battery cells. The concept is based on an innovative and agile production technology that allows flexible battery formats with the possibility of a quick recipe change for continuous cell production. The aim is to achieve sustainable production with minimal use of raw materials, minimizing raw material waste and paste loss. The process control strategy is based on an adaptive, digital concept to ensure high paste quality with the highest degree of automation and minimum energy consumption. Continuous mixing using an extruder is a recommended option to avoid a process interruption with the subsequent process steps.

Funding: BMBF

The aim of the AgiloBat cluster project is to develop an agile production system for manufacturing cell assemblies from format-flexible pouch cells with modular process control and end-to-end quality assurance. The fully automated production system consists of robot cells in which a controllable microenvironment is maintained. This eliminates the need for large drying rooms and avoids the introduction of moisture by humans. We are investigating and modelling the mixing and dispersion effect of a twin-screw extruder for process integration in battery cell production. The development of a digital twin with SPH and compartment models contributes to the simulation-based optimization of the process. By integrating inline measurement technology, the mixing process can be monitored in real time.

Funding: Carl Zeiss Stiftung Nexus

As our society continues to rely heavily on digital interactions, cryptography and blockchain technology play a

critical role in shaping a trustworthy and transparent future. Digital one-way functions (d-OWF), exemplified by

cryptographic hash functions like SHA-256 form the backbone of secure communications and decentralized ledgers. In

essence, they quickly provide a deterministic output for any given input, while it is impossible to analytically find

the corresponding input for any given output (inverse problem). The most prominent application example of is the

cryptocurrency Bitcoin where consensus on which transactions are added to the blockchain is reached without a central

institution by the so-called proof of work (PoW). It involves solving specific inverse problems of SHA-256 by trial

and error and requires computational power (work) on a massive scale.

Due to the ever-increasing environmental impact of modern blockchain applications, the PDHS group aims to establish a

new field of research focusing on so-called physicochemical one-way functions (pc-OWF). In a nutshell, processes in

particle technology are being investigated that serve as a replacement for the deterministic and digital OWF.

Encryption is based on unique process outputs (e.g. product specifications) and a vast input space regarding process

parameters. Decryption, i.e. a solution of an inverse problem, requires time and effort, forming an applicable Proof

of Physical Work for blockchain technology.

Undergraduate & Postgraduate, Winter Term

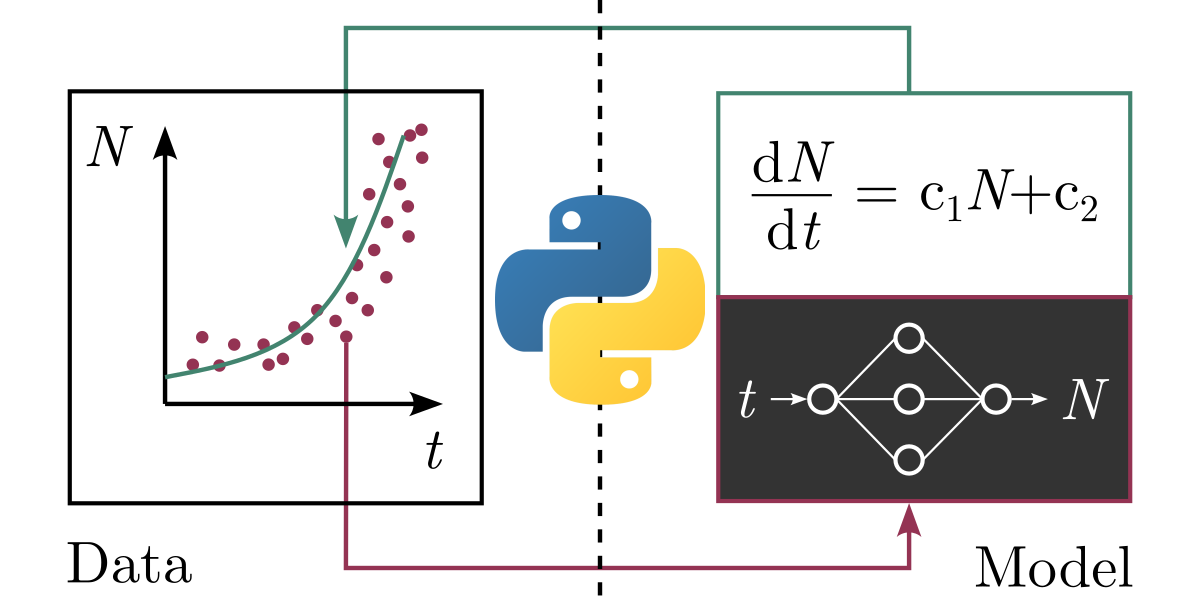

The focus of the course is on learning the basics and developing familiarity with the Python programming language. The fundamentals of optimization, regression, data integration into physical models, and the solution of simple differential equations are taught as applications (examples) throughout the semester. Valuable tools for automated data processing are taught, which are becoming more and more important in the context of the increasing digitalization of research and industry.

Postgraduate, Summer Term

This lecture focuses on the fundamental laws and technical realization of solid mixing, stirring and particle agglomeration processes. It establishes the relationships between product, operating, and design parameters. Selected topics include statistical methods, flow properties, scale-up, and surface forces. The course also introduces the basics of process simulation and provides insight into current research projects.

If you want to get in touch please write us an email to contact ∂ pdhs-group com.

The PDHS Group is affiliated with the

Institute of Mechanical Process Engineering and Mechanics at the

Karlsruhe Institute of Technology (KIT) .

You can find us at:

Strasse am Forum 8